- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

1.Simple installation. Plug and play, no additional drivers needed.

2.Multiple cut and crease . For some hard/thick materials, one time cut/crease is not enough, need 2 or 3 times to get nice cutting/creasing results. The cutting and creasing can be separated operation, for better cutting/creasing performance.

3.One-click repeat function. Great for cutting same jobs, just need to replace paper, press "Back to Origin", then press "Repeat", no skilled people also run it easily.

4.Continue cutting. If you need to process two or more sheets, when cutting second paper, users can replace first paper, save time for replacing papers.

5.Reverse cutting/creasing. It's necessary for professional users who always like perfect results.

6.Compatible OS. VICUT Vulcan series flatbed cutting machine can support both Windows & Mac OS.

ITEM | FC500VC | FC700VC |

Configuration | Digital servo system, Flatbed | |

Media hold-down method | Vacuum suction | |

Maximum cutting speed | 700 mm/s (10 to 700 mm/s ) | |

Cutting pressure | Tool 1: Max. 5.88N (600gf) Tool 2: Max. 5.88N (600gf) | |

Effective cutting area | 495x685mm | 790x1085mm |

Mountable media(Y-axis direction) | 640mm | 940mm |

Minimum character size | 5mm square | |

Mechanical resolution | 0.005mm(5pm) | |

Programmable resolution | HP-GL: 0.025mm | |

Repeatability | 0.1mm | |

Standard interfaces | USB2.0(FullSpeed) / U-Disk / Ethernet | |

Memory | 32MB | |

Command sets | HP-GL | |

Number of tools | 3 tools | |

Tool types | Cutter blade/Calibration tool/Creasing tool | |

Operating screen | 4.3-inch touch LCD | |

Power supply | 100 to 240 VAC, 50/60 Hz (Auto switching) | |

Power consumption | Max.150VA(machine),Max.550W(vacuum pump) | |

Operating environment | Temperature:10 to 35 degrees C(35 to 95 degrees F) | |

Humidity | 35 to 75% RH(non-condensing) | |

External dimensions | 981(Y)x977(X)x1047(H)mm | 1420(Y)x1212(X)x1050(H)mm |

Packaging dimensions | 115x110x61cm (machine) 47x43x37cm (vacuum pump) | 525x430x61cm (machine) 47x43x37cm (vacuum pump) |

G.W. / N.W. | 105kg/77kg (machine) 23/20kg (vacuum pump) | 154kg/104kg (machine) 23/20kg (vacuum pump) |

1.Simple installation. Plug and play, no additional drivers needed.

2.Multiple cut and crease . For some hard/thick materials, one time cut/crease is not enough, need 2 or 3 times to get nice cutting/creasing results. The cutting and creasing can be separated operation, for better cutting/creasing performance.

3.One-click repeat function. Great for cutting same jobs, just need to replace paper, press "Back to Origin", then press "Repeat", no skilled people also run it easily.

4.Continue cutting. If you need to process two or more sheets, when cutting second paper, users can replace first paper, save time for replacing papers.

5.Reverse cutting/creasing. It's necessary for professional users who always like perfect results.

6.Compatible OS. VICUT Vulcan series flatbed cutting machine can support both Windows & Mac OS.

ITEM | FC500VC | FC700VC |

Configuration | Digital servo system, Flatbed | |

Media hold-down method | Vacuum suction | |

Maximum cutting speed | 700 mm/s (10 to 700 mm/s ) | |

Cutting pressure | Tool 1: Max. 5.88N (600gf) Tool 2: Max. 5.88N (600gf) | |

Effective cutting area | 495x685mm | 790x1085mm |

Mountable media(Y-axis direction) | 640mm | 940mm |

Minimum character size | 5mm square | |

Mechanical resolution | 0.005mm(5pm) | |

Programmable resolution | HP-GL: 0.025mm | |

Repeatability | 0.1mm | |

Standard interfaces | USB2.0(FullSpeed) / U-Disk / Ethernet | |

Memory | 32MB | |

Command sets | HP-GL | |

Number of tools | 3 tools | |

Tool types | Cutter blade/Calibration tool/Creasing tool | |

Operating screen | 4.3-inch touch LCD | |

Power supply | 100 to 240 VAC, 50/60 Hz (Auto switching) | |

Power consumption | Max.150VA(machine),Max.550W(vacuum pump) | |

Operating environment | Temperature:10 to 35 degrees C(35 to 95 degrees F) | |

Humidity | 35 to 75% RH(non-condensing) | |

External dimensions | 981(Y)x977(X)x1047(H)mm | 1420(Y)x1212(X)x1050(H)mm |

Packaging dimensions | 115x110x61cm (machine) 47x43x37cm (vacuum pump) | 525x430x61cm (machine) 47x43x37cm (vacuum pump) |

G.W. / N.W. | 105kg/77kg (machine) 23/20kg (vacuum pump) | 154kg/104kg (machine) 23/20kg (vacuum pump) |

1.Camera system.The flatbed FC-500VC/FC700VC uses a high-resolution camera to accurately detect registration marks (as small as 5 mm) and reg marks can be seen on both color and transparent materials. The ability to scan small reg marks saves materials and thus reduces production costs. The ability to scan four reg marks within less than 3 seconds saves production time and reduces costs even further.

2.User friendly touch screen.Easy toggle of vacuum suction: ON - fast/stable hold, OFF - easy replacement of next item ; Easy toggle of arrow key speeds for carriage control: Fast (x10) / Slow (x1) ; Single key press to set origin or return to origin - guarantees accurate positioning. Re-cut button to instantly repeat last job.

3.Advanced contour cutting. The Vulcan flatbed efficiently handles materials loaded on a slant and also compensates for size/shape distortions. Precise and accurate cuts are assured with our proprietary four mark high-tech detection algorithm.

4.Network interface.

A.Stable communications over long distances

B.Control one flatbed cutting plotter from multiple computers

C.Control different flatbed cutting plotters from one computer

5.U-Disk function. PLT-files saved on USB thumb drives (U-disk) can be used for direct output. This means that the FC-500VC/FC-700VC can be used without being connected to a computer.

6.QR-code system. The flatbed cutter reads QR-codes on the printed media, allowing automatic matching of print and cut files. This both speeds production and eliminates any chance of mismatched files.

7.SignCut Pro.Work with SignCut Pro software from Sweden, lifetime technical support and continually updating.

1.Camera system.The flatbed FC-500VC/FC700VC uses a high-resolution camera to accurately detect registration marks (as small as 5 mm) and reg marks can be seen on both color and transparent materials. The ability to scan small reg marks saves materials and thus reduces production costs. The ability to scan four reg marks within less than 3 seconds saves production time and reduces costs even further.

2.User friendly touch screen.Easy toggle of vacuum suction: ON - fast/stable hold, OFF - easy replacement of next item ; Easy toggle of arrow key speeds for carriage control: Fast (x10) / Slow (x1) ; Single key press to set origin or return to origin - guarantees accurate positioning. Re-cut button to instantly repeat last job.

3.Advanced contour cutting. The Vulcan flatbed efficiently handles materials loaded on a slant and also compensates for size/shape distortions. Precise and accurate cuts are assured with our proprietary four mark high-tech detection algorithm.

4.Network interface.

A.Stable communications over long distances

B.Control one flatbed cutting plotter from multiple computers

C.Control different flatbed cutting plotters from one computer

5.U-Disk function. PLT-files saved on USB thumb drives (U-disk) can be used for direct output. This means that the FC-500VC/FC-700VC can be used without being connected to a computer.

6.QR-code system. The flatbed cutter reads QR-codes on the printed media, allowing automatic matching of print and cut files. This both speeds production and eliminates any chance of mismatched files.

7.SignCut Pro.Work with SignCut Pro software from Sweden, lifetime technical support and continually updating.

| Muffler. Reduce the sound level of vacuum pump. suitable for vacuum pump more than 750W. Mostly used in office which require cutter works quietly. |

| Vacuum pump. Powerful vacuum pump with acoustic cover, offering enough power to hold the printed sheets on the working table. |

| Pressure relief valve. Unique design, stabilize air pressure, ensure the steady work of suction system, prolong the service life of vacuum pump. |

| Double side rubber cutting Mat. The green self-healing mat is ideal for obtaining crisp cuts on thinner materials.This cutting mat can be used on both sides, greatly saving the cost of users. |

| Grey felt cutting mat. This cutting mat is perfect for achieving deeper creasing lines and cuts on thicker substrates. It's also very durable. |

| Creasing Tool. Creasing tool with ceramic ball point, creasing effect is better while protect the material, longer service life, easy to replace. |

| Calibration tool. Used for setting up and calibrate cutter before machine working. |

| Blade holder. This precision engineered components sits in the dual tool head and holds the cutting blade of choice. The tool is adjustable manually to obtain the desired length of blade-tip. |

| Cutting blade 60 degree. Replacement 60° angle good for cutting thicker,more dense material. 5 Pack of Durable Replacement Blades. Fine sharpened tip excellent for detail work. |

| Cutting blade 30 degree. Replacement 30° Blade for the Vulcan SC-350 Sheet Cutter 5-pack of blades good for cutting most materials. |

| Muffler. Reduce the sound level of vacuum pump. suitable for vacuum pump more than 750W. Mostly used in office which require cutter works quietly. |

| Vacuum pump. Powerful vacuum pump with acoustic cover, offering enough power to hold the printed sheets on the working table. |

| Pressure relief valve. Unique design, stabilize air pressure, ensure the steady work of suction system, prolong the service life of vacuum pump. |

| Double side rubber cutting Mat. The green self-healing mat is ideal for obtaining crisp cuts on thinner materials.This cutting mat can be used on both sides, greatly saving the cost of users. |

| Grey felt cutting mat. This cutting mat is perfect for achieving deeper creasing lines and cuts on thicker substrates. It's also very durable. |

| Creasing Tool. Creasing tool with ceramic ball point, creasing effect is better while protect the material, longer service life, easy to replace. |

| Calibration tool. Used for setting up and calibrate cutter before machine working. |

| Blade holder. This precision engineered components sits in the dual tool head and holds the cutting blade of choice. The tool is adjustable manually to obtain the desired length of blade-tip. |

| Cutting blade 60 degree. Replacement 60° angle good for cutting thicker,more dense material. 5 Pack of Durable Replacement Blades. Fine sharpened tip excellent for detail work. |

| Cutting blade 30 degree. Replacement 30° Blade for the Vulcan SC-350 Sheet Cutter 5-pack of blades good for cutting most materials. |

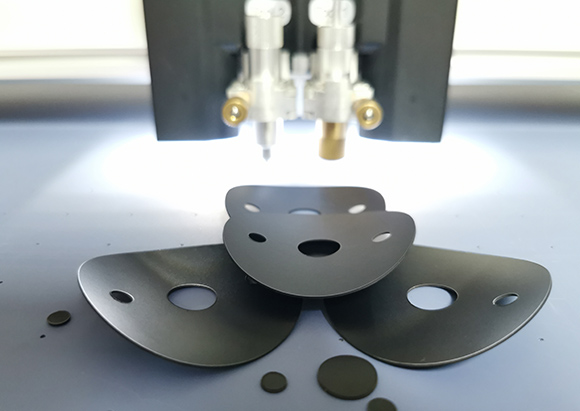

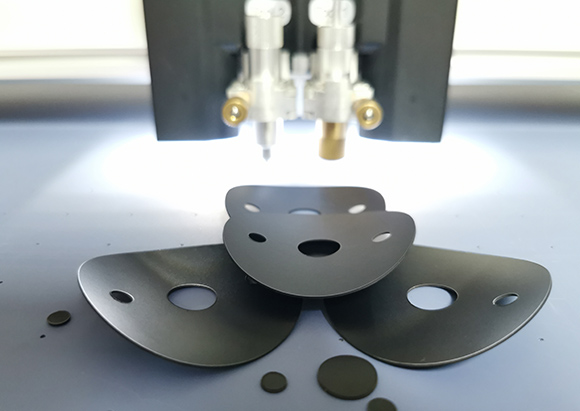

Application Fields: Prototype and light production, DIY paper crafts, tags, on-demand packaging and sheet card cutting system – also suitable for sheet labels.

Process Materials: cardboard, craft paper, fibrous cardboard, eva rubber, PVC, sandblast, vinyl, sticker, magnetic sticker,PET, TPU, reflective film and thin film etc.

Marketing Position:

FC500VC |

| Effective cutting area 495x685mm. It is suitable for placing 2pcs A3+ sheets or 4pcs A4 sheets next to each other for light production applications, enabling users to achieve higher productivity. Because of its high matching with economical printers on the market, and the competitive price,this model is currently the most popular one. |

FC700VC |

| Effective cutting area 790x1085mm.This flatbed plotter is suitable for bigger size sheets production. Four sheets of A3+ size paper can be placed on this table next to each other, and it is also suitable for 2pcs B2 sheets or a single sheet of B1 size paper. This model flatbed usually most suitable for post-processing of inkjet and press printing applications. |

working samples

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

Application Fields: Prototype and light production, DIY paper crafts, tags, on-demand packaging and sheet card cutting system – also suitable for sheet labels.

Process Materials: cardboard, craft paper, fibrous cardboard, eva rubber, PVC, sandblast, vinyl, sticker, magnetic sticker,PET, TPU, reflective film and thin film etc.

Marketing Position:

FC500VC |

| Effective cutting area 495x685mm. It is suitable for placing 2pcs A3+ sheets or 4pcs A4 sheets next to each other for light production applications, enabling users to achieve higher productivity. Because of its high matching with economical printers on the market, and the competitive price,this model is currently the most popular one. |

FC700VC |

| Effective cutting area 790x1085mm.This flatbed plotter is suitable for bigger size sheets production. Four sheets of A3+ size paper can be placed on this table next to each other, and it is also suitable for 2pcs B2 sheets or a single sheet of B1 size paper. This model flatbed usually most suitable for post-processing of inkjet and press printing applications. |

working samples

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |

|  |  |