- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

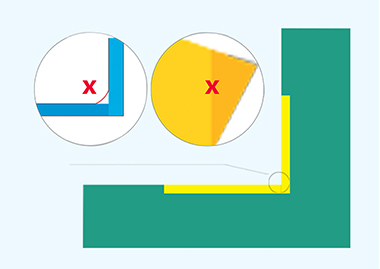

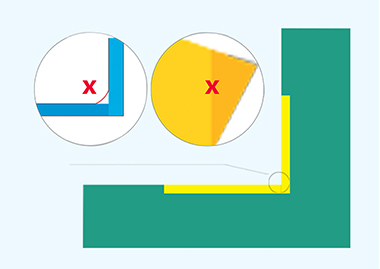

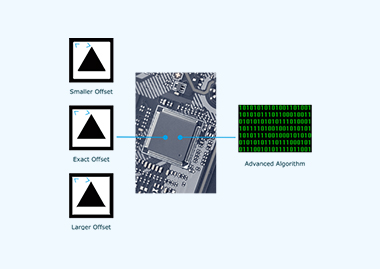

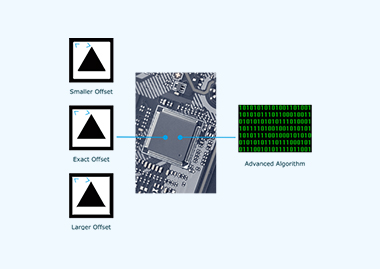

| Advanced Algorithm Obvious elimination of distorted, rounded or lifted corners. |

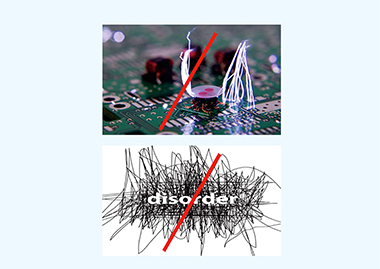

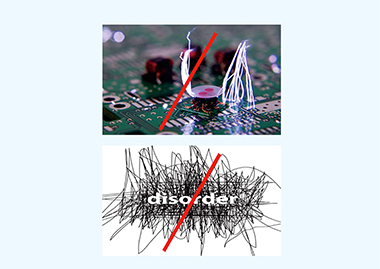

| Static free The problem of friction electrostatic interference when cutting soft thin materials is solved. |

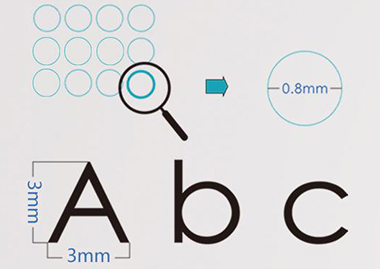

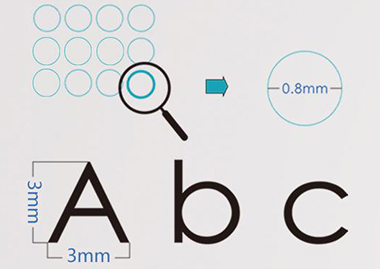

| High Precision VFR series flatbed cutter is able to cut small text strings(minimum 0.8mm circle), and it is easy to tear off the scraps. |

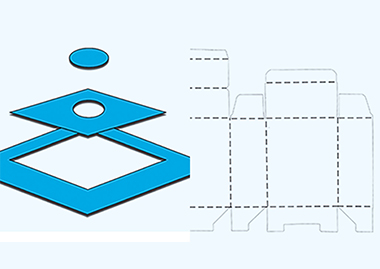

| Multiple Layers Solution For medias with multiple layers,different cutting force is applied for different layer |

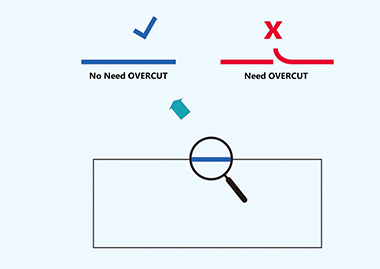

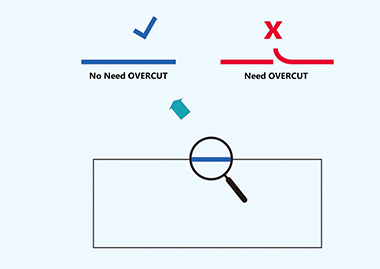

| No Need OVERCUT In every cutting path, the start and end point join with each other accurately, while no need to setup any OVERCUT. |

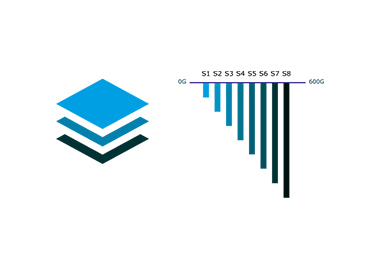

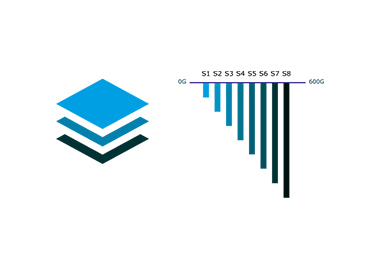

| Cutting force in 8 Step,multiple layers solution Color the cutting paths differently for various force steps, set the processing sequence as color sequence.This is good for cutting medias with multiple layers, which requires different cutting force in different layer. |

| One-click to Clear History One-click deletion button for the currently print document and clear it completely from buffer memory. |

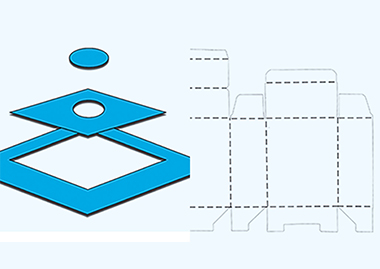

| Full cut/Half Cut/ Perforation/Marking, etc Every time you may carry out either one or both. |

| DXF Direct Output It is compatible with DXF file directly while no need any format transition. |

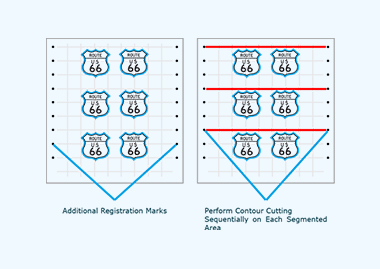

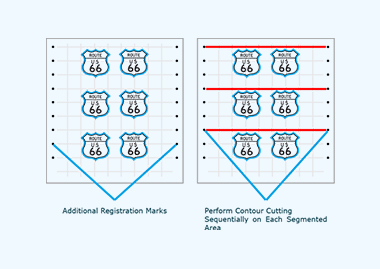

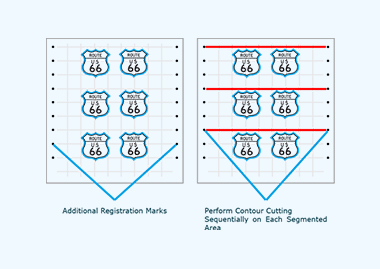

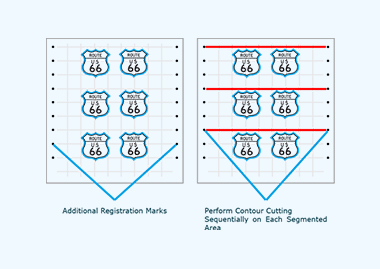

| Segmented Registration and Cutting Multiple registration marks in segmented areas, available for more precise axis alignment. Contour cutting is performed sequentially in each segmented area, which improves accuracy and tracking for heavier media or media that has been laminated during cutting big size image. |

| Handshake Protocol We supply Software Development Kit/SDK to match with user’s software, provide technical support,meet customization requirements. |

Specifications

Model | VFC90 |

Working size on X axis | Non-contour cutting: 735mm; Contour cutting: 725mm |

Working size on Y axis | Sheet media: 900mm; roll media: whole roll |

Max.media width | 800mm |

Cut media thickness | 0.03mm-1.5mm |

Applicable media | Soft and medium rigidity medias |

Method to fix media | Vacuum table(1.1kw vacuum pump with muffler) |

Method to feed media | Conveyor belt & roll media bracket |

Max.cutting speed | 600mm/s |

Max.cutting force | 600G/5.8N in 8 steps |

Cutting force setup | Adjustable in every 1G |

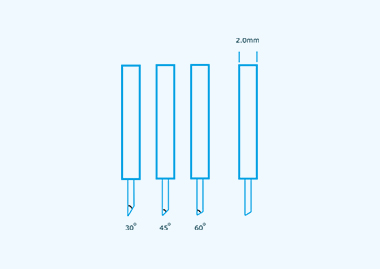

Cutter blade diameter | Φ2.0mm |

Cutter blade angles | 60˚ |

Dotted lines cutting | included |

Drive | AC Servo |

Mechanical resolution | 0.0125mm |

Compatible OS | Win 10/8/7/XP |

Memory buffer | 2MB |

Software | CDR.Plugin/Maintop, Cadlink/Flexi |

LCD language | English/Chinese |

File format | HP-GL, PLT, DXF, CAM |

Port in standard | USB, U-Disk |

Reg marks detection | CCD Camera |

Power input | 110V/220V,50-60HZ |

Power consumption | 2200W(including vacuum pump) |

Working tools | 1pcs blade holder, 1pcs pen holder, 3 pcs cutting blades |

Media bracket | included |

Packing size(L-W-H) | 1600x1400x1240mm |

Weight (N.W) | 210kg/305kg |

| Advanced Algorithm Obvious elimination of distorted, rounded or lifted corners. |

| Static free The problem of friction electrostatic interference when cutting soft thin materials is solved. |

| High Precision VFR series flatbed cutter is able to cut small text strings(minimum 0.8mm circle), and it is easy to tear off the scraps. |

| Multiple Layers Solution For medias with multiple layers,different cutting force is applied for different layer |

| No Need OVERCUT In every cutting path, the start and end point join with each other accurately, while no need to setup any OVERCUT. |

| Cutting force in 8 Step,multiple layers solution Color the cutting paths differently for various force steps, set the processing sequence as color sequence.This is good for cutting medias with multiple layers, which requires different cutting force in different layer. |

| One-click to Clear History One-click deletion button for the currently print document and clear it completely from buffer memory. |

| Full cut/Half Cut/ Perforation/Marking, etc Every time you may carry out either one or both. |

| DXF Direct Output It is compatible with DXF file directly while no need any format transition. |

| Segmented Registration and Cutting Multiple registration marks in segmented areas, available for more precise axis alignment. Contour cutting is performed sequentially in each segmented area, which improves accuracy and tracking for heavier media or media that has been laminated during cutting big size image. |

| Handshake Protocol We supply Software Development Kit/SDK to match with user’s software, provide technical support,meet customization requirements. |

Specifications

Model | VFC90 |

Working size on X axis | Non-contour cutting: 735mm; Contour cutting: 725mm |

Working size on Y axis | Sheet media: 900mm; roll media: whole roll |

Max.media width | 800mm |

Cut media thickness | 0.03mm-1.5mm |

Applicable media | Soft and medium rigidity medias |

Method to fix media | Vacuum table(1.1kw vacuum pump with muffler) |

Method to feed media | Conveyor belt & roll media bracket |

Max.cutting speed | 600mm/s |

Max.cutting force | 600G/5.8N in 8 steps |

Cutting force setup | Adjustable in every 1G |

Cutter blade diameter | Φ2.0mm |

Cutter blade angles | 60˚ |

Dotted lines cutting | included |

Drive | AC Servo |

Mechanical resolution | 0.0125mm |

Compatible OS | Win 10/8/7/XP |

Memory buffer | 2MB |

Software | CDR.Plugin/Maintop, Cadlink/Flexi |

LCD language | English/Chinese |

File format | HP-GL, PLT, DXF, CAM |

Port in standard | USB, U-Disk |

Reg marks detection | CCD Camera |

Power input | 110V/220V,50-60HZ |

Power consumption | 2200W(including vacuum pump) |

Working tools | 1pcs blade holder, 1pcs pen holder, 3 pcs cutting blades |

Media bracket | included |

Packing size(L-W-H) | 1600x1400x1240mm |

Weight (N.W) | 210kg/305kg |

| Advanced Tool Carriage The tool carriage adopts the structure of sports car, using of silent voice coil motor makes it outstrip it’s rivals. The tool carriage is featured as fast, agile and no overheat for long-time non-stop operation. It is a leading tool carriage in the same field in China. |

| Suction cup feeding device Several suction cups are installed on the beam of the cutter to help drag the media to the forefront of the machine for convenient processing. |

| Vacuum System Strong air flow to hold down the media flatly and tightly against the table top so that the tool carriage can perform fast, accurate cutting / plotting. |

| Auto Feeding Conveyor System Conveyor is able to accomplish long seamless cutting / plotting. With the combination of CCD camera, fast and accurate nesting / contour cutting is performed. |

| Roll Feeding Device It is smooth to feed media with the media bracket, user may setup the bracket according to media feature and specs. The bracket improves productivity. |

| Grating Ruler Inevitably material surface is not level from point to point, the grating ruler is applied to measure the distance between blade tip and material surface, and the cutting depth is adjusted in every 0.01mm by the controller accordingly. Then the blade travels up and down as material surface goes to keep the same cutting depth at any position of the tool paths across the entire table. In short, Grating Ruler is of key importance for consistent cutting depth. |

| Making Blade-tip Compensation by chip Our system makes blade-tip compensation by hardware(main board) instead of software, the cutter works with constant high precision no matter what kind of CAD / CAM software is applied. |

| Servo Motor / Closed Loop Control Intelligent servos bring out smooth acceleration, big torque, precise cutting / plotting operation, excellent durability and volume production. Servos ensure the vinyl cutter to run at Max. Speed: 600mm/s. |

| Fast Registration Marks Detection with CCD Camera With our dedicated software, it is able to generate contours in one-click, and it is easy to add registration marks.CCD camera, used in combination with related software is applied to detect the intricate dieless contours fast and more efficiently. Problems caused by position error of human, poor quality printing are resolved. CCD camera is applied for wide varieties of medias |

| Segmented Aera Cutting Operation Additonal registration marks are available for more precise axis aligment.Countour cutting is performed sequentially in each segmented area,which improves accuracy and tracking for heavier media or media that has been laminated. |

| Leading Compatibility Leading the same industry, VFC is able to adapt to the latest version of popular CAD / CAM software, such as AutoCAD, Adobe Illustrator, Coreldraw, Flexisign, Signmaster; Various pattern software in automotive aftermarket like 3M™ Pattern and Solutions Center (PSC), Core by LLUMAR, INTEGO are already compatible to this system. |

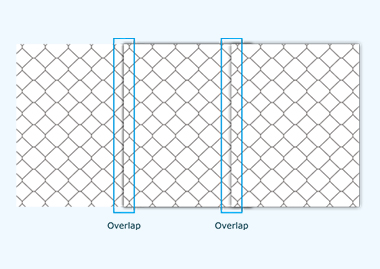

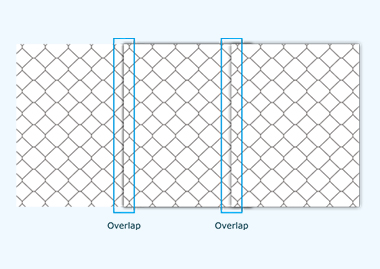

| Intelligent Bleeding for Easier Overlap Operation Intelligent Bleeding function makes overlap operation easier for the installers, this feature is very important for making and installation of big signs / indicators. |

| USB memory/ Duplicate cutting jobs offline Users are enabled to duplicate the cutting jobs offline, which is much convenient than doing that with connecting to PC by USB cord. The function of duplicating cutting jobs with USB memory is a leading technology that developed by our-self. This feature is important for efficient volume production. |

| Quality Components For outstanding performance and long-term reliable working, we only use world class brand name components like BANDO belt,NMB bearing, Ultra-silence Guides made by WON Korea, etc. |

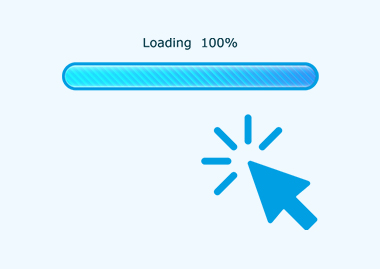

| One-click to Load Print Driver Optimized the process of loading print driver by one-click. User can easily send cutting jobs by any CAD that with printer feature. |

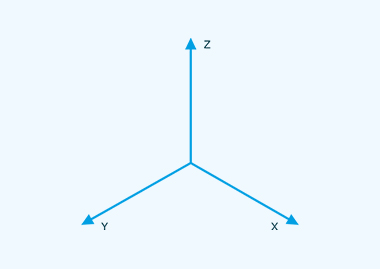

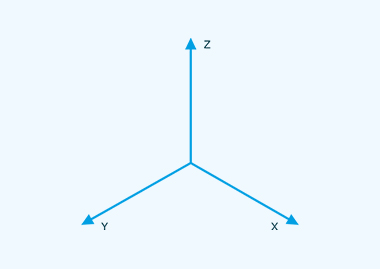

| Leading Calibration Industry leading technology is applied to calibrate the perpendicular between different axes and the parallelism between track of gantry and table top. |

| Fine Blader Hoder Cutter blade runs precisely and womt drop cutting thick .sticky medias. |

| Clean Smooth Edge Quality The granting ruler and correspondent cutting force management deliver clean smooth eage quality, even for the most complex jobs. Pealing off the cutting piece/waste material easily can cut down workload greatly for the users. |

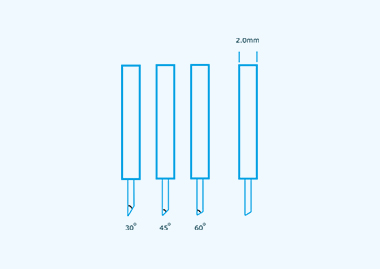

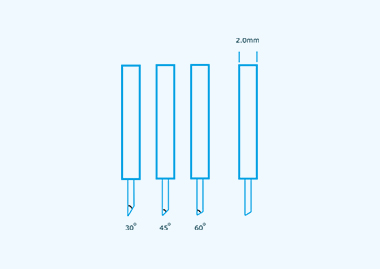

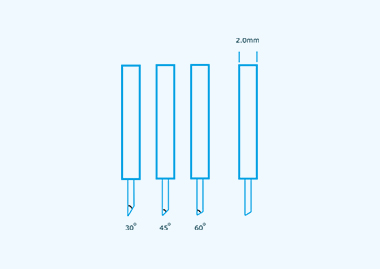

| Series Cutter Blades Available Angle :30˚/ Φ2.0mm for prismatic reflective sheeting, thick media or small character Angle: 60˚/ Φ2.0mm for relfective film . Angle: 45 ˚/ Φ2.0mm for PPF. |

| Advanced Tool Carriage The tool carriage adopts the structure of sports car, using of silent voice coil motor makes it outstrip it’s rivals. The tool carriage is featured as fast, agile and no overheat for long-time non-stop operation. It is a leading tool carriage in the same field in China. |

| Suction cup feeding device Several suction cups are installed on the beam of the cutter to help drag the media to the forefront of the machine for convenient processing. |

| Vacuum System Strong air flow to hold down the media flatly and tightly against the table top so that the tool carriage can perform fast, accurate cutting / plotting. |

| Auto Feeding Conveyor System Conveyor is able to accomplish long seamless cutting / plotting. With the combination of CCD camera, fast and accurate nesting / contour cutting is performed. |

| Roll Feeding Device It is smooth to feed media with the media bracket, user may setup the bracket according to media feature and specs. The bracket improves productivity. |

| Grating Ruler Inevitably material surface is not level from point to point, the grating ruler is applied to measure the distance between blade tip and material surface, and the cutting depth is adjusted in every 0.01mm by the controller accordingly. Then the blade travels up and down as material surface goes to keep the same cutting depth at any position of the tool paths across the entire table. In short, Grating Ruler is of key importance for consistent cutting depth. |

| Making Blade-tip Compensation by chip Our system makes blade-tip compensation by hardware(main board) instead of software, the cutter works with constant high precision no matter what kind of CAD / CAM software is applied. |

| Servo Motor / Closed Loop Control Intelligent servos bring out smooth acceleration, big torque, precise cutting / plotting operation, excellent durability and volume production. Servos ensure the vinyl cutter to run at Max. Speed: 600mm/s. |

| Fast Registration Marks Detection with CCD Camera With our dedicated software, it is able to generate contours in one-click, and it is easy to add registration marks.CCD camera, used in combination with related software is applied to detect the intricate dieless contours fast and more efficiently. Problems caused by position error of human, poor quality printing are resolved. CCD camera is applied for wide varieties of medias |

| Segmented Aera Cutting Operation Additonal registration marks are available for more precise axis aligment.Countour cutting is performed sequentially in each segmented area,which improves accuracy and tracking for heavier media or media that has been laminated. |

| Leading Compatibility Leading the same industry, VFC is able to adapt to the latest version of popular CAD / CAM software, such as AutoCAD, Adobe Illustrator, Coreldraw, Flexisign, Signmaster; Various pattern software in automotive aftermarket like 3M™ Pattern and Solutions Center (PSC), Core by LLUMAR, INTEGO are already compatible to this system. |

| Intelligent Bleeding for Easier Overlap Operation Intelligent Bleeding function makes overlap operation easier for the installers, this feature is very important for making and installation of big signs / indicators. |

| USB memory/ Duplicate cutting jobs offline Users are enabled to duplicate the cutting jobs offline, which is much convenient than doing that with connecting to PC by USB cord. The function of duplicating cutting jobs with USB memory is a leading technology that developed by our-self. This feature is important for efficient volume production. |

| Quality Components For outstanding performance and long-term reliable working, we only use world class brand name components like BANDO belt,NMB bearing, Ultra-silence Guides made by WON Korea, etc. |

| One-click to Load Print Driver Optimized the process of loading print driver by one-click. User can easily send cutting jobs by any CAD that with printer feature. |

| Leading Calibration Industry leading technology is applied to calibrate the perpendicular between different axes and the parallelism between track of gantry and table top. |

| Fine Blader Hoder Cutter blade runs precisely and womt drop cutting thick .sticky medias. |

| Clean Smooth Edge Quality The granting ruler and correspondent cutting force management deliver clean smooth eage quality, even for the most complex jobs. Pealing off the cutting piece/waste material easily can cut down workload greatly for the users. |

| Series Cutter Blades Available Angle :30˚/ Φ2.0mm for prismatic reflective sheeting, thick media or small character Angle: 60˚/ Φ2.0mm for relfective film . Angle: 45 ˚/ Φ2.0mm for PPF. |

| Vacuum blower. VFC90 Auto feeding flatbed cutter work with stable quality vacuum blower, continually working more than 24 hours without overheating issues. |

| Fine blade holder. Cutter blade runs precisely and won't drop cutting thick, sticky medias. |

| Series cutting blades available. Angle: 30°/Φ 2.0mm for thicker media or small character Angle: 60°/Φ2.0mm for reflective film Angle: 45°/Φ2.0mm for PPF/PET film |

| Vacuum blower. VFC90 Auto feeding flatbed cutter work with stable quality vacuum blower, continually working more than 24 hours without overheating issues. |

| Fine blade holder. Cutter blade runs precisely and won't drop cutting thick, sticky medias. |

| Series cutting blades available. Angle: 30°/Φ 2.0mm for thicker media or small character Angle: 60°/Φ2.0mm for reflective film Angle: 45°/Φ2.0mm for PPF/PET film |

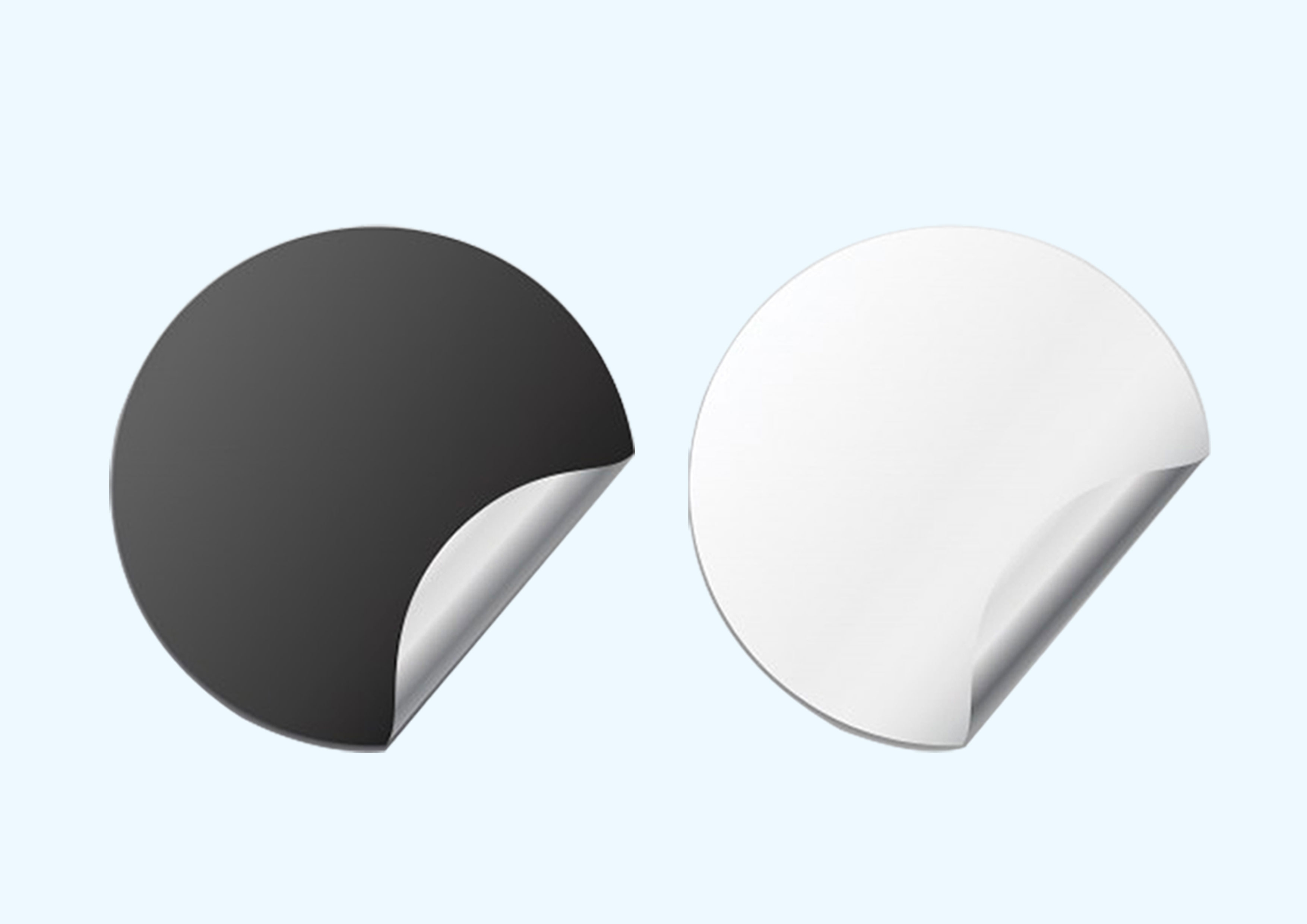

Suitable materials

1.PET Film for DTF Printer

DTF ,direct transfer film,which is a new technology for heat transfer-digital offset heat transfer.

2.Other Flexible Media Thickness From 0.03-1.5mm.

Such as reflective films,heat transfer films,paint protection films/PPF,vehicle wrap,window tint ,vinyl sticker, managet sticker, sandblast resist rubber, mobile phone decoration film, multiple layer film, film for flexible Circuit ,glass film, PVC film and more.

3.Paper Cards

Up to 500gsm.

Suitable Field: Automotive aftermarket, vehicle decoration, traffic signs industry, sign makers, packaging, apparel signing, shoes designing, bags designing, composite industry, offset printing, samples making, POP displays, and more.

|  |  |  |

working samples

|  |  |

|  |  |

|  |  |

|  |  |

Suitable materials

1.PET Film for DTF Printer

DTF ,direct transfer film,which is a new technology for heat transfer-digital offset heat transfer.

2.Other Flexible Media Thickness From 0.03-1.5mm.

Such as reflective films,heat transfer films,paint protection films/PPF,vehicle wrap,window tint ,vinyl sticker, managet sticker, sandblast resist rubber, mobile phone decoration film, multiple layer film, film for flexible Circuit ,glass film, PVC film and more.

3.Paper Cards

Up to 500gsm.

Suitable Field: Automotive aftermarket, vehicle decoration, traffic signs industry, sign makers, packaging, apparel signing, shoes designing, bags designing, composite industry, offset printing, samples making, POP displays, and more.

|  |  |  |

working samples

|  |  |

|  |  |

|  |  |

|  |  |