- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

The most ideal digital blade cutter alternative to laser cutter Supporting both of Roll to Sheet & Roll to Roll!

• All-In-One solution .

Lamination, Rewinder for the Lamination Backing, matrix removal, slitting, trimming, sheeting. It also features an automated web guide to ensure your product is running smooth through the machine at all times.

• Artificial Intelligence applied.

CCD camera recognizes registration marks to select job automatically, distance between heads can be adjusted automatically by job data. It automatically calculates optimal usage of heads in each step of cutting for a specific job.

• 9M/min cutting speed (10cm x 10cm rectangles)

VR3350D has single station with 4 heads as default, can be updated to 12 heads with 3 stations to reach 27m/min speed.

• Max. 350mm x 600mm size label cutting.

• Embedded PC with big LCD touch screen.

Specifications

Model Name | Digital Label Die Cutter VR3350D |

Maxi. roll diameter | 450mm |

Cutting media width | 40--350mm |

Max. label size | 350x600mm |

Mini. label length | 10mm |

Min. distance between labels | 2mm |

Min.distance from mark to edge | 2mm |

Min.distance between jobs | 2mm |

Max. die cutting speed | 9m per minute (depends on label shape and size) |

No. of die cutting heads | 4pcs heads(default), up to 12pcs heads with 3 stations. |

Die cutting blades | Tungsten steel blades |

Die cutting precision | 0.1mm (duplicate) |

Web guide | Ultrasonic guided correction(BST from Germany) |

Tension system | 6-axis automatic tension |

Code Scanner | CCD camera |

Mark Sensor | Reflective photoelectric sensor |

Slitting width | 10 ~ 330mm |

Slitting blades | 4pcs(standard ), up to 15pcs |

Slitting speed | 100m/min |

Slitting precision | 0.1mm |

Data transfer method | PC direct |

Working voltage | 100-240V AC, 2000W |

Machine dimension | 200cm(L) x 119cm(W) x 157cm(H) |

Weight(N.W/G.W) | 1200kg |

Packing size | 1700*1150*1570mm |

Optional function | Multiple die cutting heads up to 12pcs |

Multiple slitting units up to 15pcs | |

Upper rewinder | |

Film base paper removing device | |

Inline sheeter |

The most ideal digital blade cutter alternative to laser cutter Supporting both of Roll to Sheet & Roll to Roll!

• All-In-One solution .

Lamination, Rewinder for the Lamination Backing, matrix removal, slitting, trimming, sheeting. It also features an automated web guide to ensure your product is running smooth through the machine at all times.

• Artificial Intelligence applied.

CCD camera recognizes registration marks to select job automatically, distance between heads can be adjusted automatically by job data. It automatically calculates optimal usage of heads in each step of cutting for a specific job.

• 9M/min cutting speed (10cm x 10cm rectangles)

VR3350D has single station with 4 heads as default, can be updated to 12 heads with 3 stations to reach 27m/min speed.

• Max. 350mm x 600mm size label cutting.

• Embedded PC with big LCD touch screen.

Specifications

Model Name | Digital Label Die Cutter VR3350D |

Maxi. roll diameter | 450mm |

Cutting media width | 40--350mm |

Max. label size | 350x600mm |

Mini. label length | 10mm |

Min. distance between labels | 2mm |

Min.distance from mark to edge | 2mm |

Min.distance between jobs | 2mm |

Max. die cutting speed | 9m per minute (depends on label shape and size) |

No. of die cutting heads | 4pcs heads(default), up to 12pcs heads with 3 stations. |

Die cutting blades | Tungsten steel blades |

Die cutting precision | 0.1mm (duplicate) |

Web guide | Ultrasonic guided correction(BST from Germany) |

Tension system | 6-axis automatic tension |

Code Scanner | CCD camera |

Mark Sensor | Reflective photoelectric sensor |

Slitting width | 10 ~ 330mm |

Slitting blades | 4pcs(standard ), up to 15pcs |

Slitting speed | 100m/min |

Slitting precision | 0.1mm |

Data transfer method | PC direct |

Working voltage | 100-240V AC, 2000W |

Machine dimension | 200cm(L) x 119cm(W) x 157cm(H) |

Weight(N.W/G.W) | 1200kg |

Packing size | 1700*1150*1570mm |

Optional function | Multiple die cutting heads up to 12pcs |

Multiple slitting units up to 15pcs | |

Upper rewinder | |

Film base paper removing device | |

Inline sheeter |

| photos | description |

| Multiple die cutting heads. VR3350D works with multiple die cutting heads, up to 12 heads(3 stations) work at once, highly increase working efficiency. |

| CCD Camera Identify System. The CCD camera positioning and identify system can recognize the sequence codes of each jobs,so that job exchanges can be done automatically smooth during feeding and cutting. |

| Reflective photoelectric mark sensor. The positioning sensor scans the marked points printed on the material to obtain the cutting dies information and feed it back to the machine control system, so as to realize the digital cutting. |

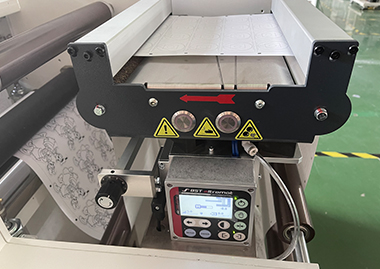

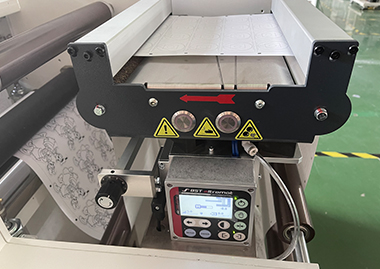

| High Precision feeding Detection System(BST from Germany). Utilizing high precision ultrasonic web-guide system from Germany, make sure the paper feeding in correct way, ready for next die cutting step. |

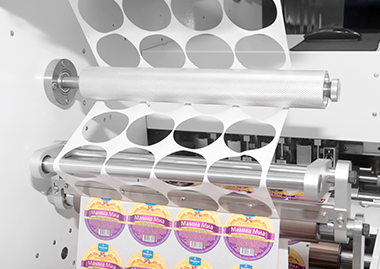

| Cold lamination. Automatic lamination before die cutting, makes finishing labels more durable and more widely application. The back liner film remover is optional. |

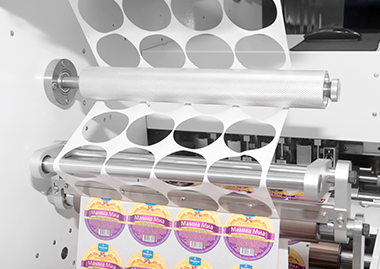

| Automatic waste removal and tension system. Under the 6-axis automatic tension of the waste discharge system, the label cutting waste paper will be automatically removed and separated from the winding, so as to obtain a clean label roll for the next process. |

| Slitting system. Utilize square blades, automatically cut the label paper into small rolls as needed,up to 15pcs blades can be used. Maximum slitting speed can reach to 100m/min. |

| Down rewinder. Default main rewinder for roll to roll process. |

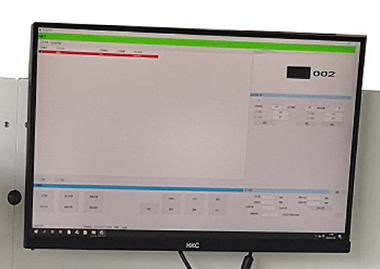

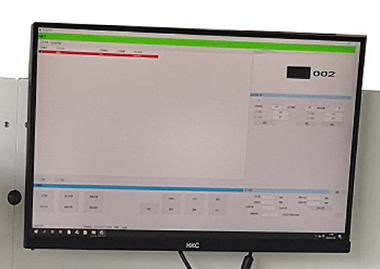

| Easy-to-use dedicated software. • Running status can be seen in a real-time. • Support file database. • Choose the quantity of the heads based on graphics. • Intelligent cutting with trajectory optimization. • Adjust heads distance automatically. • Auto-generate the working records. |

| Upper rewinder. (Optional) Optional upper rewinder to separate labels in every second row after slitting. |

| Inline Roll to Sheet Cutting System.(optional) The optional built-in sheet cutting module can be in-lined with the main die-cutting to perform the roll to sheet cutting process. |

| Film base paper removing device.(optional) In some areas, there is backing paper on the cold laminating film, which can be removed before laminating by this device. |

| photos | description |

| Multiple die cutting heads. VR3350D works with multiple die cutting heads, up to 12 heads(3 stations) work at once, highly increase working efficiency. |

| CCD Camera Identify System. The CCD camera positioning and identify system can recognize the sequence codes of each jobs,so that job exchanges can be done automatically smooth during feeding and cutting. |

| Reflective photoelectric mark sensor. The positioning sensor scans the marked points printed on the material to obtain the cutting dies information and feed it back to the machine control system, so as to realize the digital cutting. |

| High Precision feeding Detection System(BST from Germany). Utilizing high precision ultrasonic web-guide system from Germany, make sure the paper feeding in correct way, ready for next die cutting step. |

| Cold lamination. Automatic lamination before die cutting, makes finishing labels more durable and more widely application. The back liner film remover is optional. |

| Automatic waste removal and tension system. Under the 6-axis automatic tension of the waste discharge system, the label cutting waste paper will be automatically removed and separated from the winding, so as to obtain a clean label roll for the next process. |

| Slitting system. Utilize square blades, automatically cut the label paper into small rolls as needed,up to 15pcs blades can be used. Maximum slitting speed can reach to 100m/min. |

| Down rewinder. Default main rewinder for roll to roll process. |

| Easy-to-use dedicated software. • Running status can be seen in a real-time. • Support file database. • Choose the quantity of the heads based on graphics. • Intelligent cutting with trajectory optimization. • Adjust heads distance automatically. • Auto-generate the working records. |

| Upper rewinder. (Optional) Optional upper rewinder to separate labels in every second row after slitting. |

| Inline Roll to Sheet Cutting System.(optional) The optional built-in sheet cutting module can be in-lined with the main die-cutting to perform the roll to sheet cutting process. |

| Film base paper removing device.(optional) In some areas, there is backing paper on the cold laminating film, which can be removed before laminating by this device. |

| Die Cutting Blades. Special 45 degree 10U die cutting blade, suitable for cutting 0.25 mm thick adhesive label materials such as sticker, coated paper, synthetic paper, PP, PET, etc. |

| Die Cutting Blades holder. Precision blade holder, built-in bearing design, cooperate with machine blade compensation function, make cutting more smooth. Easy to install the blade and adjust the distance between the blade tips. |

| Slitting blades. Tungsten steel ring blades, high cutting precision to divide big rolls into smaller one. |

| Die Cutting Blades. Special 45 degree 10U die cutting blade, suitable for cutting 0.25 mm thick adhesive label materials such as sticker, coated paper, synthetic paper, PP, PET, etc. |

| Die Cutting Blades holder. Precision blade holder, built-in bearing design, cooperate with machine blade compensation function, make cutting more smooth. Easy to install the blade and adjust the distance between the blade tips. |

| Slitting blades. Tungsten steel ring blades, high cutting precision to divide big rolls into smaller one. |

Applicable Industry: VR320 roll to roll label finisher is mainly used in producing wide range of labels including blank labels, ink labels, chemical labels, beverage labels, bottled water labels, chili source labels,coffee labels, cosmetic labels, home appliance label,toiletries label, gum label,wine labels and more.

Applicable Materials: Stickers, Paper, PP, BOPP, PET, PVC & More!

working samples

|  |  |

|  |  |

|  |  |

Applicable Industry: VR320 roll to roll label finisher is mainly used in producing wide range of labels including blank labels, ink labels, chemical labels, beverage labels, bottled water labels, chili source labels,coffee labels, cosmetic labels, home appliance label,toiletries label, gum label,wine labels and more.

Applicable Materials: Stickers, Paper, PP, BOPP, PET, PVC & More!

working samples

|  |  |

|  |  |

|  |  |